Manufacturing

Transforming Ideas into Reality. At BzsLink, we specialize in turning concepts into tangible products. Our dedicated team of engineers, coupled with our extensive range of machinery, enables us to take your idea from the initial stages of ideation to the realization of a final, market-ready product. With our expertise and resources, we are committed to bringing your ideas to life efficiently and effectively.

Manufacturing With BzsLink

The Process

Manufacturing can be a complex endeavor, but with BzsLink, we strive to simplify the process for you. Our dedicated manufacturing team will be by your side, providing guidance and support every step of the way.

Step 1. The Briefing

Provide the BzsLink manufacturing team with a comprehensive briefing on the component/product, including drawings and details regarding its functionalities. Sharing as much information as possible will enhance efficiency and effectiveness throughout the process. The more details you provide, the better equipped BzsLink will be to determine how we can best assist you in various areas.

Step 2. Review quote

During this phase of the process, the BzsLink manufacturing team will generate a comprehensive project quotation, including the pricing per piece during the production stage. Additionally, we will provide you with a timeline that outlines the expected duration for each stage of the project. Our goal is to ensure transparency and provide you with a clear understanding of the project's cost and timeline.

Step 3. Review Prototype

At this stage, the BzsLink manufacturing team will construct and deliver a prototype for your project. This prototype serves as a tangible representation of your product design. Once you have reviewed and approved the prototype, we can proceed to the next stage of the project.

Step 4. Production

During this stage, all the individual parts of your product will be manufactured and assembled within the BzsLink workshop. Our skilled team will meticulously produce and assemble each component to ensure the highest quality standards are met. To accommodate varying quantities and timelines, we have the capability to set up a total of 15 assembly lines.

Step 5. Packaging and Shipment

BzsLink goes beyond manufacturing and offers comprehensive packaging solutions as well. Our specialized packaging design department is equipped to create customized packaging that aligns with your specific requirements. From conceptualization to the final design, we ensure that the packaging perfectly complements your product. Once the manufacturing process is complete, the final products will be carefully packed using the newly designed packaging. We take pride in providing end-to-end services, and our logistics team will ensure a smooth and timely delivery of the packaged products to your designated warehouse.

Step 6. After Sales Service

At BzsLink, our commitment to customer satisfaction extends beyond the delivery of the final products. We stand by our quality and provide reliable after-sales service to address any issues that may arise. If you encounter any concerns or problems with the received products, our dedicated team will promptly investigate the matter and work towards finding a satisfactory solution. Your satisfaction is our priority, and we strive to ensure that any issues are resolved in a timely and efficient manner. Rest assured, we are here to support you throughout your journey with BzsLink.

Plastic Injection Moulding

BzsLink takes pride in offering comprehensive in-house plastic injection molding services, providing support at every stage of your project. With an impressive fleet of 101 injection molding machines, we are well-equipped to handle any requirement or production volume. Our range of services includes:

Product Design

Precision Mould Production

Mould Design

Injection Moulding

We acknowledge that injection molding can be a complex manufacturing process. However, with our expertise and experience, we make it seamless for you. Our in-house engineering department is dedicated to guiding you through every step of the process, ensuring your project is well-prepared for mass production. To commence your project, simply click the button below and let us embark on this journey together.

Die Casting

BzsLink specializes in the manufacturing of complex, durable, and highly-efficient custom molds. We excel in producing molds with low tolerance levels, ensuring precision and accuracy in the final products. Whether you require low-volume or high-volume production cycles, we have the capabilities to meet your needs. Our in-house team of skilled engineers is equipped to handle any requirement, ensuring that every step of the die casting process is carried out under our close supervision. This approach allows us to maintain stringent quality control measures and protect the intellectual property of your designs.

Aluminium Die Casting

Magnesium Die Casting

In-house Precision CNC

Low-Pressure Die Cast

Zinc Die Casting

Mould Design

High-pressure Die Cast

Surface Finishing

We understand that each die casting project is unique, and at BzsLink, we believe in providing personalized solutions. That's why we offer free customized quotes for every project, without any obligations. We value the opportunity to learn more about your specific requirements and provide you with an accurate and tailored quote. To get started, simply click the button below and provide us with more details about your project. Our team will review the information and promptly get back to you with a comprehensive quote. We look forward to working with you and bringing your project to life.

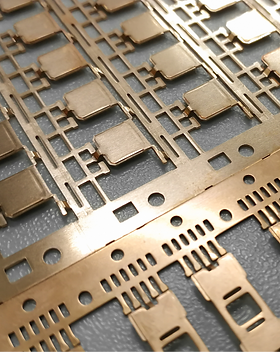

Metal Stamping

If you're in need of a high-speed and precision metal stamping solution, BzsLink is here to help. We specialize in metal stamping for complicated metal parts, utilizing state-of-the-art equipment and techniques to ensure exceptional quality and accuracy. Our in-house team of experienced engineers will be by your side, providing guidance and support throughout the entire process. No matter the challenges that arise, we are committed to finding innovative solutions to overcome them.

We specialise in 3 methods of metal stamping: Short-run stamping, Precision stamping and Progressive stamping

Our metal stamping workshop is equipped with machines capable of working with a wide range of materials, including stainless steel, aluminum, nickel-silver, brass, copper, and spring steel. This versatility allows us to accommodate different project requirements and material specifications.

While we specialize in the three methods of metal stamping mentioned earlier, we understand that each project is unique and may require a customized production plan. We encourage you to reach out to us with your specific metal stamping project details, and our team will work closely with you to develop a tailored solution that meets your requirements.

Short-Run Stamping

Precision Stamping

Progressive Stamping

CNC Machining & Turning

BzsLink offers two precision CNC machining services: CNC machining and CNC turning. Our state-of-the-art CNC machines enable us to deliver exceptional precision and accuracy for your projects, ensuring the lowest tolerances possible.

With our extensive experience, we have successfully handled numerous prototypes and parts for companies with complex projects. We take pride in our commitment to quality, and we only accept projects that we can confidently guarantee the results.

Our turnaround time is efficient, and depending on the complexity of the project, we can deliver within a few days. We understand the importance of timely delivery and strive to meet your project's deadlines.

CNC Machining

CNC Turning

CNC machining is a versatile technology that can be applied to a wide range of materials, including woods, plastics, and metals. Whether you need precision cuts, intricate designs, or complex shapes, our CNC machines can deliver exceptional results across different materials.

Silicone Compression Moulding

BzsLink specializes in providing high-quality silicone solutions for a wide range of industries, including medical/healthcare, consumer, and aerospace. Our expertise in silicone manufacturing makes us a reliable long-term partner for your silicone part and product needs.

We offer top-quality silicone materials that meet rigorous industry standards, ensuring the durability, flexibility, and reliability of the final products. With our advanced manufacturing capabilities, we can uphold precision tolerances to meet your specific requirements and deliver consistent results.

Whether you need custom silicone parts, prototypes, or finished products, our team is dedicated to delivering excellence and exceeding your expectations. Partner with BzsLink for reliable silicone manufacturing solutions that meet the highest standards of quality and performance.